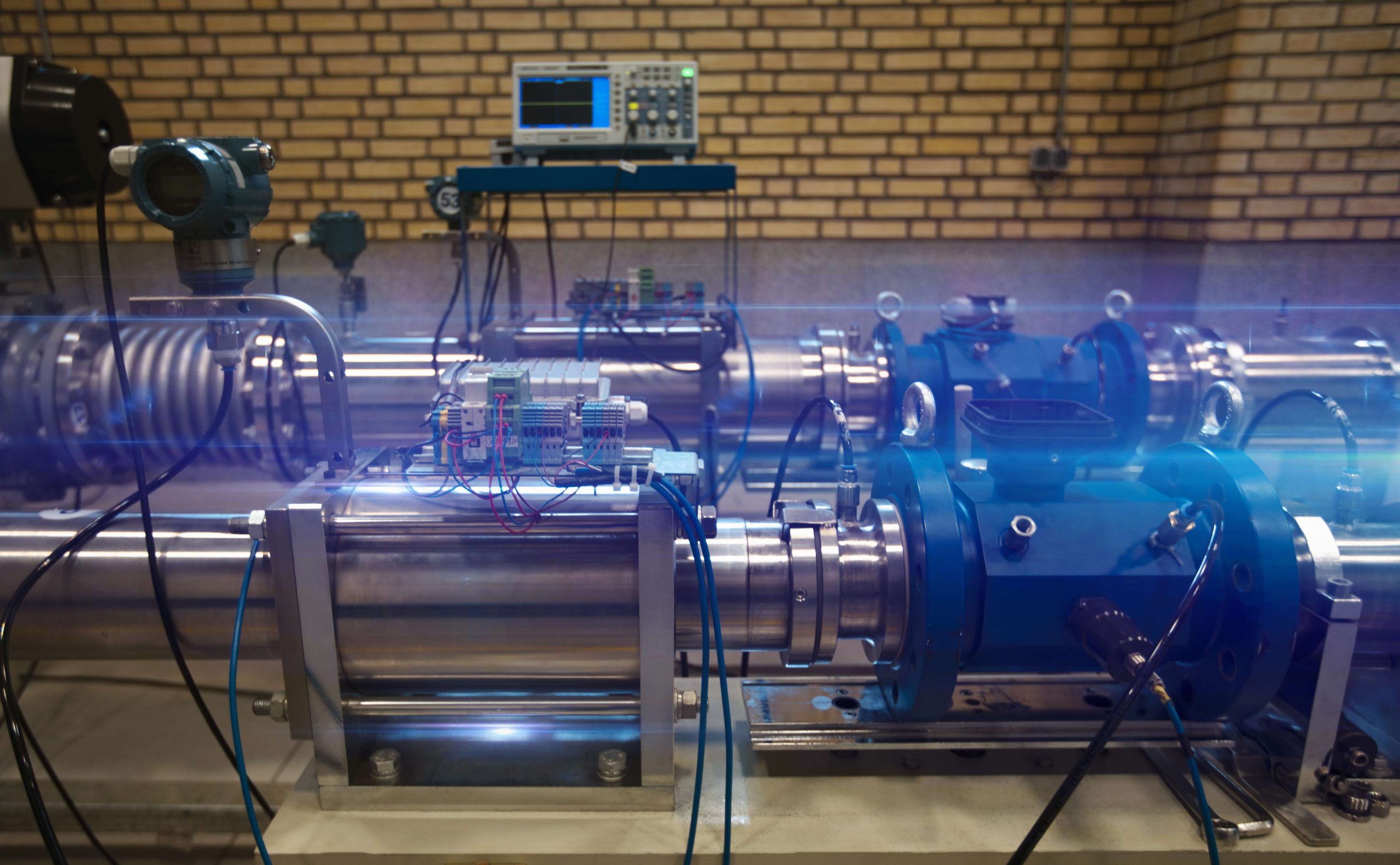

Installation and Commissioning of Turbine Flow Meters

The installation and commissioning of turbine flow meters require special care due to their mechanical work principals. The first and most important step is selecting a suitable installation location. The meter must be installed in a section of the pipeline with sufficient straight and smooth runs upstream and downstream to prevent damage to the rotor blades and ensure accurate measurement.

During commissioning, the correct rotor rotation direction is verified, and the flow computer parameters are configured based on the meter’s calibration factor (Meter Factor).

Installation and commissioning by the specialists at Delta Gas Mobin Group help minimize pressure drop, extend the meter’s service life, and improve measurement accuracy.