Online Stack Dust Measurement

There is dust everywhere in our environment. Industrial processes are the reason for dust and because of the general population growth dust particles continue to increase. The permanent control of dust emissions is becoming more and more important. Especially considered worldwide the potential and the necessity are high. Country-specific, legal conditions specify the compliance with limit values for certain plants.

Devices used for the continuous dust measurement register in the wider sense the physical changes caused by the particles in the measuring system converting them into electrical signals. For that the measured object can be analysed directly in exhaust gas channel (in-situ measurement) or a partial volume flow is collected and fed into a measuring device (extractive sampling).

Periodic dust concentration measurements are usually used as a standard reference method (gravimetric) for calibration of continuous dust concentration measuring devices.

Our solutions:

- In-situ Triboelectric dust measurement:

As result of the in-situ techniques, the measurement signals derive from the direct interaction of light or a triboelectric probe with the dust particles in the exhaust gas channel. For evaluation the scattered light or the absorbance of a transmitted light beam respectively triboelectricity can be used.

The in-situ measuring devices are only suitable for the measurement of dust in dry gases.

- In-Situ Laser Dust Measurement:

The monitors are designed for measurement across pipes, stacks and ducts with typical path lengths of 0.5 – 10 m.

LaserDust™ Monitors use a transmitter/receiver configuration to measure the dust concentration along the optical line of sight. Our true non-contact approach is superior to point type dust meters.

With innovative laser technology the LaserDust™ combines two measurement principles in one instrument.

- At low dust levels it operates with forward scattered light technology:

The incident laser light is scattered by dust particles and collected onto a solid-state sensor for dust quantification. This highly sensible mode enables detection limits of < 0.5 mg/Nm3 and is unaffected by dust depositing on the windows. - At high dust levels the LaserDust™ will measure transmittance or opacity:

Light absorption by dust particles is captured by a 2nd sensor.

- Extractive dust measurement:

In case of wet or saturated with water vapour gases, the existing water droplets and aerosols create also light scattering effects, which distort the measurements results. Therefore in these cases the extractive measurement technique should be selected. The basis of the extractive methods constructs a preferably isokinetic partial flow extraction from the main gas flow. As measuring principles the scattered light measurement or the triboelectric measurement can be carried out.

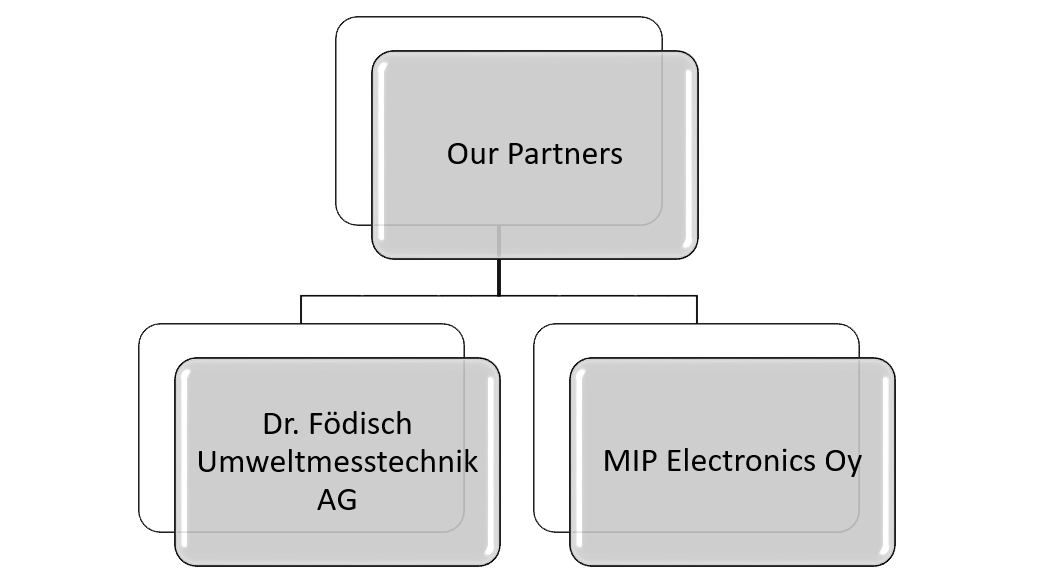

Our partners on continues emission monitoring systems: